PRODUCTION PROCESS

Cultivation

Aurospirul spirulina is cultivated in shallow ponds of approx. 15cm deep. Nutrients (minerals and salts) are added to obtain the optimum conditions for the algae to grow. The strongly alkaline water (pH 10,2) ensures that no other algae, micro-organism or microcystins can develop in the culture.

The culture in the ponds is stirred several times a day, in order to stimulate photosynthesis.

Harvesting

When the water is heavy with spirulina, it is scooped up and passed through a set of filters. The spirulina biomass is collected in the finest filter, where it is drained and cleansed with water.

The cleansing process is finished when the water seeping through the filter stays fully transparant.

Pressing

The fresh biomass is folded into a finely meshed fabric, then placed between two granite slabs and pressed.

As much excess water as possible is pressed out (up to 80%). The spirulina mass thus becomes a solid paste.

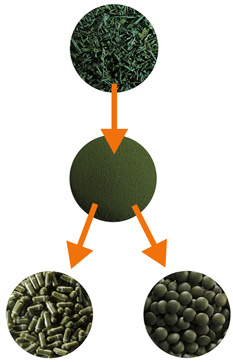

Drying

The spirulina mass is squeezed into fine 'spaghettini' and laid to dry in the sun. Due to the favourable climate in South India, this typically takes a few hours only.

During the process, the spirulina takes its characteristic flavour, but only mildly so due to the open-air drying system. Aurospirul sun-dried spirulina has a pleasant fragrance and flavour.

The final stage of the drying process is done in a hot-air dryer, in order to achieve the exact humidity, as well as a 100% food-safe product.

The result: pure, sun-dried spirulina crunchy, ready for consumption.

Pressing and Packaging

Part of the spirulina is grounded to a fine powder, part of which in turn is used to fill capsules and make tablets.

Products are then carefully measured, packed and sealed. Leaflets are included in the packing.

In our dispatch department, products are handled for worldwide distribution.

For more details, consult our catalogue.